The Wootzano Success Story

How a start-up became a pioneering robotics company in just three years.

Corporate Communications Manager

(she/her)

How a start-up became a pioneering robotics company in just three years.

24 hours a day, seven days a week, Wootzano’s Avarai robots can tirelessly trim, pick and pack fresh produce in a highly dexterous manner. In food packaging facilities, these robots can minimise food waste, reduce labour costs, and bring fresher produce to supermarket shelves faster than ever. With the upcoming release of the robotic system and the signing of a landmark deal, Wootzano’s robots may transform the fresh produce industry.

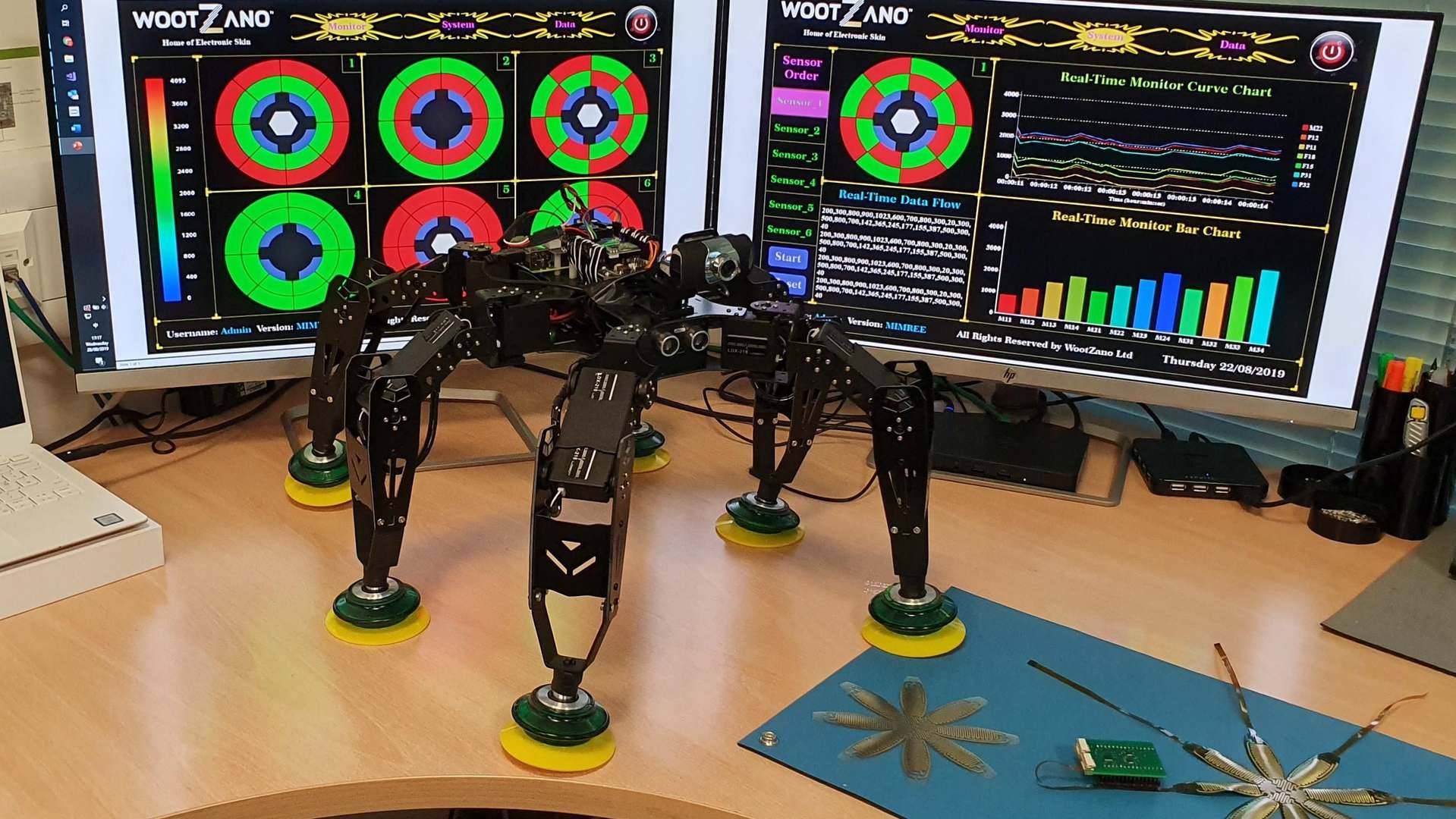

Wootzano Ltd – founded in 2018 – is a British robotics company based at NETPark in Sedgefield that is transforming the fresh produce supply chain. Avarai, the company’s state-of-the-art robotic fruit packaging system, utilises unique technology to carefully handle and pack delicate produce, allowing workers to ease away from the physically demanding labour they are subjected to, for more health-conscious roles. Avarai utilises sensors and machine-learning algorithms along with Wootzkin, a unique patented electronic skin to detect the appropriate force needed to hold produce in a human-like manner without causing damage.

The Avarai system is also capable of simultaneously detecting various forms of rot, mould, and ripeness, giving producers confidence in the quality of the produce they distribute. Data from the sensors is continually sent to a machine learning module, which can help the robots detect when grip is loosening and correct it to prevent an item from falling and bruising. In this way, Wootzano’s robots can carry out the physically demanding labour often required to tackle some of the challenges faced in the industry, such as high labour costs and recruitment shortages, whilst helping to ensure better working conditions.

A cloud network further enhances Avarai’s machine learning capabilities to enable the robots to not only learn from themselves, but also from others in the network. This network enables updates to be sent remotely to help optimise the robots’ performance, as well as providing the ability to pre-emptively flag when replacement parts are needed to minimise downtime. Combining all these features means that Wootzano’s robots can deliver impressive handling capabilities that are constantly improving to ensure reliable productivity to customers.

Rapid growth during the pandemic

Since its early days based at CPI’s National Printable Electronics Centre, Wootzano has successfully broken into the lucrative agricultural robot market. The company has expanded rapidly with a series of successes in the form of funding, awards, and distribution agreements.

Now, with the release of Avarai, Wootzano has signed a £300 million deal with one of the largest fresh produce pack houses in Britain –believed to be the most significant contract of any robotics company in the UK to date. The market for agricultural robots is huge, due in part to difficulties in sourcing labour especially in peak season, but also due to a desire to reduce contact between human workers and food, exacerbated by the pandemic.

Wootzano’s robots provide an excellent return on investment, capable of carrying out their role over a 24-hour period, demonstrating a cost effect benefit for packing factories. In addition to this, Avarai can prevent supply chain delays, ensure safe handling, and limit food waste.

CPI's Impact

Since 2017, Wootzano has transferred their processing facilities from Edinburgh to CPI’s National Electronics Centre. During their ongoing relationship, Wootzano has had access to office space, cleanrooms, and equipment. This has enabled Wootzano to further develop and upscale their processing of WootZkin; a unique electronic skin, which gives robots their impressive handing capabilities.

With this new deal signed, Wootzano has made great strides bringing automation to the fresh produce industry. In 2020, Wootzano expanded and moved into their new premises, remaining at NETPark, to accommodate their robotics assembly operations and an ever-growing team. CPI continues to build on the relationship and support Wootzano’s increased activity on the manufacturing readiness curve, through the provision of access to cleanrooms, equipment, technical support, and technical expertise.

An exciting future ahead

Wootzano’s robots will ultimately help to ensure a reliable supply of fresh produce, helping to meet the nutritional needs of the growing population. By upgrading the often repetitive, laborious human jobs involved in fruit packing, the robots offer the possibility of creating new jobs for workers with better conditions, in addition to the cost and productivity benefits for pack houses. Avarai robots currently handle tomatoes and grapes, with plans to adapt to other types of delicate produce soon.

Initially targeting the largest players in the industry, over the next few years Wootzano hopes to make its robots more affordable for smaller packaging facilities to enable widespread adoption. The potential of Wootzano’s dexterous robots extends beyond agriculture, with projects also underway for their use in off-shore windfarm inspection and even potential applications in prosthetics that can provide the user with a sense of feeling. With a strong foundation of patented technology, it will be exciting to see where Wootzano takes its robots next.

Enjoyed this article? Keep reading more expert insights...

CPI ensures that great inventions gets the best opportunity to become a successfully marketed product or process. We provide industry-relevant expertise and assets, supporting proof of concept and scale up services for the development of your innovative products and processes.